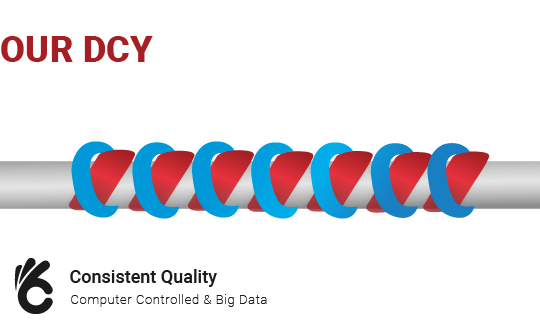

Double Covered Yarn (DCY)

The general process of this yarn is centered on a spandex covered with two main yarns which are opposite to each other. One of them is Z twist direction (that is, clockwise), and the other is S twist direction (counterclockwise direction). Both yarns wrap around the spandex (that is, outer- and -inner wrapped) using different twist angles to manufacture different fabric handfeel. Therefore, the two main yarns do not need to be the same type and different fibers as well as different specifications can also be used; the feature characteristic of the Hsin Jung process is that the matching yarn and the two main yarns can be adjusted according to customer needs.

APPLICATIONS

- Seamless Garment

- Compression Stocks

- Weft-knitted Uppers

OUR ADVANTAGE

Drawing from 40 years of experience, Hsin Jung Fiber has mastered manufacturing parameters, using electronic systems to optimize the performance of the twisted yarn module so that the detwisting and twisting time can be precisely controlled and the twist of the covered yarn can be uniform. In addition, through tension control that is almost error-free, the high-quality double-covered yarn (DCY) has high elasticity and excellent coverage, enabling customers to prevent problems such as snagging and breakage in their end products.

The 3D double covering technique from Hsin Jung Fiber can combine yarns of dissimilar functions, fully demonstrating the capacities of various types of yarn. Thus, end products with various functions and purposes can be manufactured and provided.

SPECIFICATION

| Standard | Type | Luster | ||||

|---|---|---|---|---|---|---|

| Spandex(D) | Polyester (D/F) | FDY | DTY | Bright | Semi-dull | Full-dull |

| 15 20 30 40 55 70 120 140 180 210 260 280 350 420 560 840 1120 1680 |

20/24 | v | v | |||

| 30/24 | v | v | ||||

| 40/24 | v | v | ||||

| 50/72 | v | v | ||||

| 75/36 | v | v | ||||

| 75/72 | v | v | ||||

| 75/144 | v | v | ||||

| 100/36 | v | v | ||||

| 100/96 | v | v | ||||

| 150/48 | v | v | ||||

| 150/96 | v | v | ||||

| 150/144 | v | v | ||||

| 300/96 | v | v | ||||

| 75/72/2 | v | v | ||||

| 75/144/2 | v | v | ||||

| 300/96 | v | v | ||||

| Standard | Type | Luster | ||||

|---|---|---|---|---|---|---|

| Spandex(D) | Nylon 6 (D/F) | FDY | DTY | Bright | Semi-dull | Full-dull |

| 15 20 30 40 55 70 120 140 180 210 260 280 350 420 560 840 1120 1680 |

12/5 | v | v | v | ||

| 15/3 | v | v | ||||

| 15/5 | v | v | ||||

| 17/10 | v | v | v | v | ||

| 20/7 | v | v | ||||

| 20/24 | v | v | v | v | ||

| 30/10 | v | v | ||||

| 30/24 | v | v | ||||

| 30/36 | v | v | ||||

| 40/14 | v | v | v | |||

| 40/34 | v | v | v | |||

| 40/48 | v | v | ||||

| 50/48 | v | v | ||||

| 70/24 | v | v | v | v | v | |

| 70/48 | v | v | v | v | v | |

| 70/72 | v | v | v | v | ||

| 100/24 | v | v | ||||

| 140/48 | v | v | v | |||

| 140/96 | v | v | v | v | ||

| 140/144 | v | v | v | v | ||

| 200/48 | v | v | ||||

| 210/72 | v | v | ||||

| Standard | Type | Luster | ||||

|---|---|---|---|---|---|---|

| Spandex(D) | Nylon 6.6 (D/F) | FDY | DTY | Bright | Semi-dull | Full-dull |

| 15 20 30 40 55 70 120 140 180 210 260 280 350 420 560 840 1120 1680 |

7/5 | v | v | |||

| 10/7 | v | v | v | |||

| 12/5 | v | v | ||||

| 20/7 | v | v | ||||

| 20/20 | v | v | v | |||

| 30/10 | v | v | ||||

| 30/20 | v | v | ||||

| 40/34 | v | v | v | |||

| 40/51 | v | v | ||||

| 50/34 | v | v | ||||

| 70/34 | v | v | v | |||

| 70/68 | v | v | v | v | ||

| 100/34 | v | v | ||||

| 140/136 | v | v | v | |||

※ Note: This table is a common specification, and a customized service is also available.